Power Tools Carbon Brush

Price 15.00 INR/ Piece

Power Tools Carbon Brush Specification

- Grip Type

- Firm

- Voltage

- 220V

- Power Source

- Electric

- Gauge

- Standard

- Tensile Strength

- High

- Function

- Electrical Conductivity and Wear Resistance

- Features

- Efficient Performance, Long Service Life, Low Sparking

- Surface Finish

- Smooth

- Motor Power

- Up to 800W

- Tool Type

- Power Tools Carbon Brush

- Material

- Carbon

- Handle Material

- Plastic

- Shape

- Rectangular

- Dimension (L*W*H)

- 9 mm x 5 mm x 15 mm

- Installation

- Easy to mount

- Replacement Interval

- Depends on usage condition

- Number of Pieces

- 2 pieces (1 Pair)

- Operating Environment

- Dry and Dust-Free Area

- Color

- Black & Copper

- Heat Resistance

- Up to 180°C

- Contact Material

- Copper Alloy

- Weight

- Approximately 12 grams per pair

- Current Rating

- 6A

- Packing Type

- Box / Packet

- Wear Rate

- Low

- Compatibility

- Universal for multiple models

- Application

- Suitable for various electric power tools

Power Tools Carbon Brush Trade Information

- Minimum Order Quantity

- 200 Pieces

- FOB Port

- india

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 2 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Asia, Africa

- Main Domestic Market

- All India

About Power Tools Carbon Brush

Power tool carbon brushes are crucial components in many electric power tools, such as drills, saws, and sanders. Here's an overview:Function

1. Current Transfer: Carbon brushes transfer electrical current between the stationary and rotating parts of a power tool.

2. Motor Performance: They play a vital role in maintaining optimal motor performance and efficiency.

Characteristics

1. Material: Typically made from carbon or graphite, which provides good electrical conductivity and durability.

2. Design: Brushes are designed to fit specific power tool models and motor types.

3. Wear and Tear: Carbon brushes can wear out over time, requiring replacement to maintain tool performance.

Importance

1. Tool Longevity: Properly functioning carbon brushes can extend the lifespan of power tools.

2. Performance: Well-maintained brushes ensure optimal tool performance, efficiency, and reliability.

Replacement

1. Regular Inspection: Regularly inspect carbon brushes for wear and damage.

2. Replacement: Replace brushes when necessary to prevent damage to the power tool's motor.

Universal Compatibility for Multiple Power Tools

This carbon brush is designed for a wide range of electric power tools, making it a versatile choice for manufacturers, suppliers, and traders. Its standard gauge, shape, and dimensions ensure that it fits various models seamlessly, reducing the hassle of determining individual compatibility. Whether you are working in a professional or DIY environment, this universal fit helps streamline maintenance routines.

Durable Construction and Heat Resistance

With a robust carbon body and a copper alloy contact, the brush exhibits high tensile strength and an exceptionally smooth surface finish. Engineered to withstand temperatures up to 180C and functioning on 220V electric power, it maintains low sparking and consistent conductivity. This durability extends service intervals and minimizes the frequency of replacements, even under demanding operational conditions.

Efficient Performance and User-Friendly Installation

Thanks to its low wear rate and efficient electrical conductivity, the Power Tools Carbon Brush ensures your equipment runs smoothly and effectively. Installation is simple and requires minimal effort, catering to both skilled technicians and end-users. Each packet includes two rectangular brushes with firm plastic handles, making them easy to mount and replace as needed.

FAQ's of Power Tools Carbon Brush:

Q: How do I install the Power Tools Carbon Brush?

A: To install the Power Tools Carbon Brush, ensure your power tool is disconnected from the power source. Locate the brush holder, remove the worn brushes, and insert the new brush pair firmly. The design is user-friendly, ensuring quick and straightforward installation without specialized tools.Q: What are the benefits of using this carbon brush with my electric power tools?

A: These carbon brushes provide efficient electrical conductivity and a low wear rate, resulting in long service life and minimal sparking. The copper alloy contact ensures high performance, while the heat resistance up to 180C guarantees reliability during extended operations.Q: When should I replace the carbon brush in my power tools?

A: Replacement intervals depend on usage conditions and operational environments. It's advisable to replace the carbon brush when you notice increased sparking, reduced performance, or visible wear. Regular inspections can help ensure optimal tool efficiency.Q: Where can I use this universal carbon brush?

A: The brush is suitable for various electric power tools requiring up to 800W of motor power, provided they operate in dry and dust-free conditions. Its universal compatibility makes it ideal for manufacturers, suppliers, traders, and wholesalers across India.Q: What is the process for maintaining the carbon brush?

A: Routine maintenance involves inspecting the brushes for signs of wear or damage and keeping the operating environment clean. Ensure the brush fits snugly in its holder and replace it once the length decreases significantly or the brush's performance falters.Q: What makes this carbon brush stand out in terms of durability?

A: Our carbon brush features a high-tensile carbon construction, copper alloy contacts, and a smooth surface finish. These elements minimize wear and ensure long-lasting, stable performance under high temperatures and demanding workloads.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hand Tools Category

Mason Trowel / Thapi / Mazola Karni

Price 56 INR / Piece

Minimum Order Quantity : 24 Pieces

Material : High Carbon Steel

Tool Type : Mason Trowel / Thapi / Mazola Karni

Surface Finish : Polished

Features : Corrosion Resistant, Durable, Lightweight

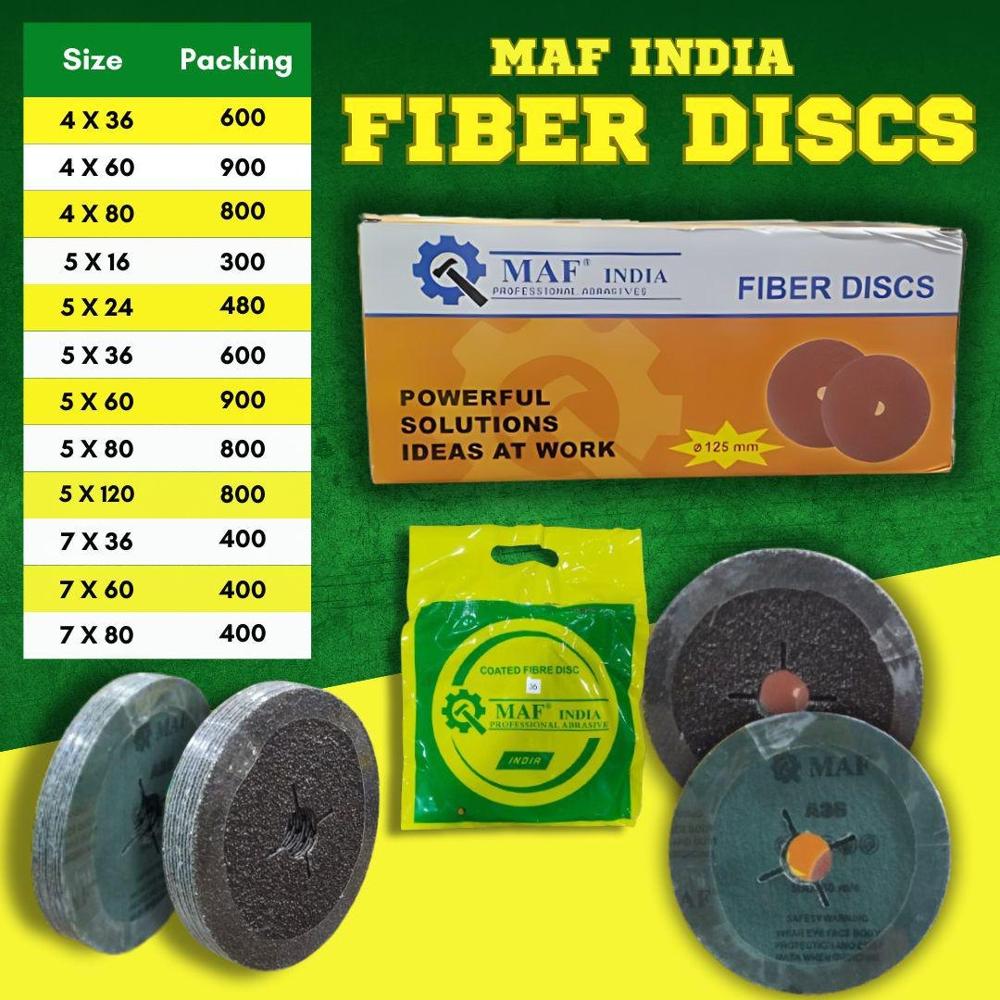

Maf India Fiber Disc 5Inch

Price 10 INR / Piece

Minimum Order Quantity : 100 Pieces

Material : Other, Resin Bonded Aluminium Oxide

Tool Type : Fiber Disc

Surface Finish : Coated Abrasive

Features : Durable, High Material Removal, Fast Cutting

Plastic Brown Grip (Wall Plug)

Price 15 INR / Piece

Minimum Order Quantity : 100 Pieces

Material : Other, Plastic (Polyethylene or similar)

Tool Type : Wall Plug (Grip)

Surface Finish : Matte, slightly textured

Features : Antislip structure, corrosion resistant, easy to install

Norton Champ Grit 80 Fibre Disc

Price 17 INR / Piece

Minimum Order Quantity : 100 Pieces

Material : Other, Aluminium Oxide

Tool Type : Fibre Disc

Surface Finish : Resin Bonded

Features : High Cutting Efficiency, Consistent Finish, Long Life

Send Inquiry

Send Inquiry