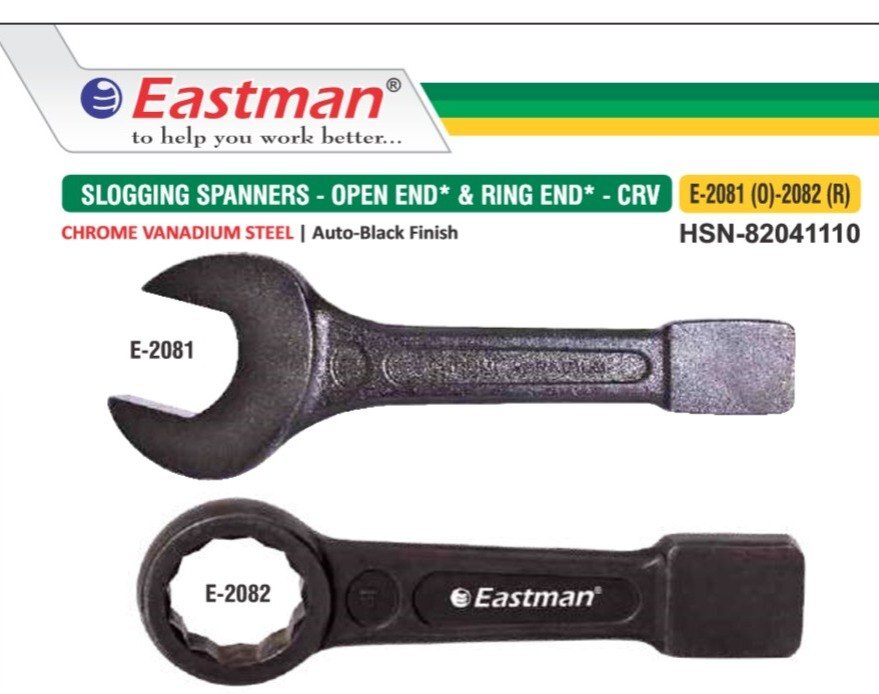

SLOGGING SPANNER OPEN END & RING END

Price 675.00 INR/ Piece

SLOGGING SPANNER OPEN END & RING END Specification

- Tensile Strength

- High Tensile Strength (as per IS 4508)

- Power Source

- Manual

- Function

- Tightening and loosening heavy-duty bolts/nuts

- Features

- Shock Resistant, Designed for Hammer Use, Rust Resistant

- Surface Finish

- Black Phosphate/Anti-Rust Coated

- Gauge

- Heavy Duty Industrial Gauge

- Grip Type

- Non-Slip Machined Surface

- Tool Type

- Slogging Spanner Open End & Ring End

- Material

- Drop Forged Carbon Steel

- Handle Material

- Metal

- Shape

- Open-End & Ring-End (Double Ended)

- Dimension (L*W*H)

- Available in sizes 24mm to 100mm (Length varies by size)

- Color

- Black

- Corrosion Resistance

- Enhanced due to phosphate coating

- Usage/Application

- Professional, Industrial Maintenance, Construction, Petrochemical Plants

- End Type

- Open End and Ring Spanner Combo

- Hardness

- 44-48 HRC

- Packaging Type

- Single piece or set, packed in polybag or box

- Weight

- Weight varies by size from 0.75 kg up to 8 kg

- Finish Type

- Matte

SLOGGING SPANNER OPEN END & RING END Trade Information

- Minimum Order Quantity

- 2 Pieces

- FOB Port

- india

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 2 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Asia, Africa

- Main Domestic Market

- All India

About SLOGGING SPANNER OPEN END & RING END

Types of Spanners1. Open-End Spanner: Has open jaws that can grip nuts or bolts from the side.

2. Ring Spanner: Has a closed ring that fits around the nut or bolt head, providing a secure grip.

Benefits of Combination Spanners

1. Versatility: A spanner with both open-end and ring-end features offers flexibility for various applications.

2. Convenience: Having both types of ends on one tool can save space in your toolbox and make it easier to work on different projects.

Applications

1. General Maintenance: Suitable for general maintenance, repair, and DIY projects.

2. Automotive: Useful for working on vehicles, machinery, and equipment.

3. Industrial: Can be used in various industrial settings for tasks that require flexibility and precision.

Engineered for Demanding Applications

Crafted to serve professional technicians and industrial operators, these slogging spanners are ideal for heavy-duty jobs that require high tensile strength and dependable grip. The drop forged carbon steel construction and black phosphate finish provide the durability and corrosion resistance necessary for extended use in tough environments such as construction sites and plants.

Versatile and Reliable Design

These tools feature both open and ring ends, accommodating a broad range of bolt and nut sizes with ease. The non-slip machined surface ensures secure handling, while the heavy-duty gauge construction gives added resilience for projects that demand the use of a hammer, making them suitable for industrial maintenance and petrochemical work.

FAQ's of SLOGGING SPANNER OPEN END & RING END:

Q: How should I use a Slogging Spanner Open End & Ring End for optimal safety and effectiveness?

A: For best results, always match the spanner size with the bolt or nut. Use the ring end for a firmer grip when possible and the open end for quicker adjustments. The design allows for hammer use when extra torque is needed. Wear protective gloves and goggles while in use to ensure safety.Q: What benefits does the phosphate black matte finish offer the slogging spanner?

A: The black phosphate matte finish provides enhanced corrosion and rust resistance, extending the lifespan of the tool even in harsh industrial or outdoor environments. This finish also reduces glare and offers a better grip.Q: Where can these slogging spanners be used effectively?

A: These spanners are ideal for settings such as construction sites, industrial maintenance workshops, and petrochemical plants. They are designed to tighten and loosen large, heavy-duty bolts and nuts that are common in these industries.Q: When should I choose a slogging spanner over a standard spanner?

A: A slogging spanner should be chosen when working with large fasteners requiring high torque, particularly where mechanical impact with a hammer is needed. Their heavy-duty construction is suitable for industrial and professional settings where standard spanners might fail.Q: What is the process for maintaining and storing the spanners?

A: After use, clean the spanner to remove debris or moisture. Store in a dry, secure place, ideally in a toolbox or the provided packaging. Regularly inspect for wear or damage to maintain safety and effectiveness during use.Q: What materials and features contribute to the spanner's high durability?

A: Constructed from drop forged carbon steel, these spanners offer high tensile strength and shock resistance. Their non-slip machined surface improves grip, while the black phosphate coating protects against rust and corrosion.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hand Tools Category

Snap off blade cutter 18mm

Price 17 INR / Piece

Minimum Order Quantity : 100 Pieces

Surface Finish : Polished Blade, Matte Handle

Tool Type : Snap Off Blade Cutter

Gauge : Blade Thickness: 0.5mm

Grip Type : Nonslip Textured Grip

Addison Hss Taper Shank Drills

Price 100 INR / Piece

Minimum Order Quantity : 5 Pieces

Surface Finish : Ground Finish

Tool Type : Taper Shank Drill

Gauge : Standard gauge as per IS 5103/ISO 235 (varies with size)

Grip Type : Taper Shank

Eastman Bi-Hexagonal Ring Spanners - Deep Offset

Price 502 INR / Piece

Minimum Order Quantity : 2 Pieces

Surface Finish : Nickel Chrome Plated

Tool Type : BiHexagonal Ring Spanner Deep Offset

Gauge : Standard Gauge (relates to specific size)

Grip Type : Polished Metal

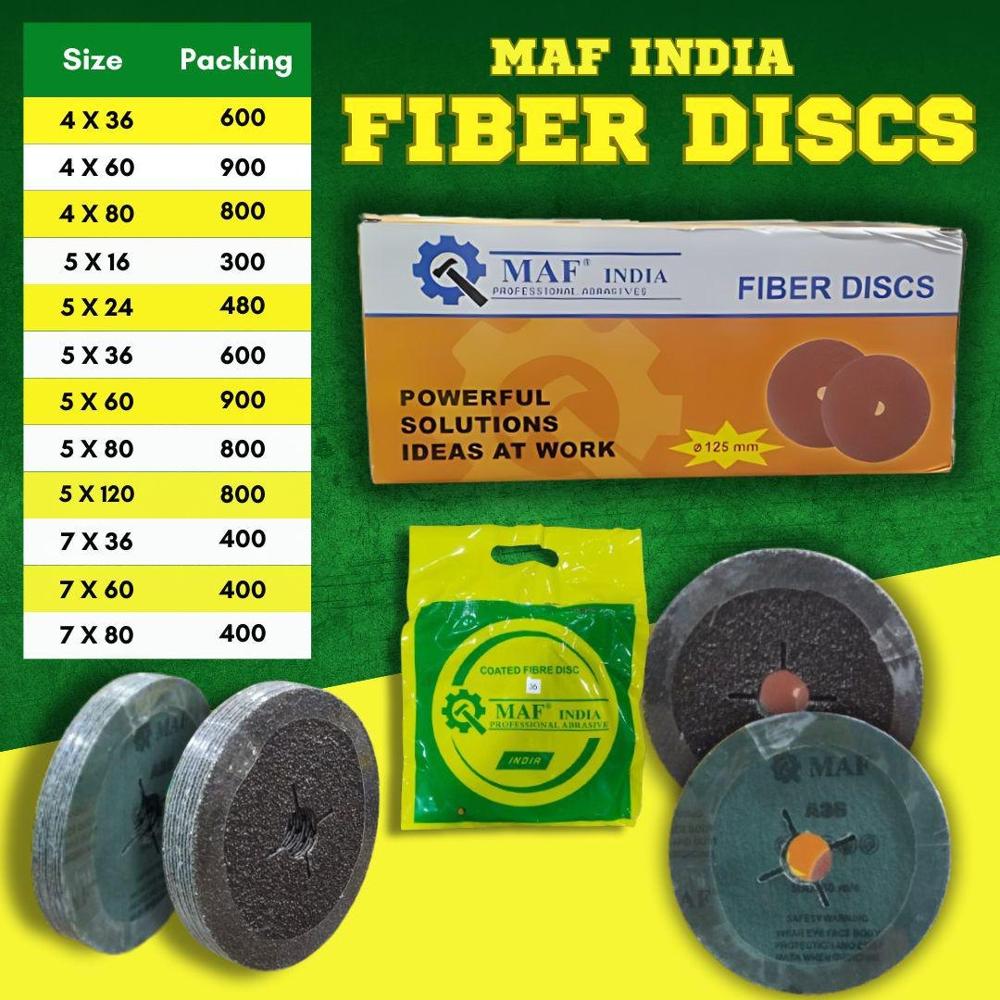

Maf India Fiber Disc 5Inch

Price 10 INR / Piece

Minimum Order Quantity : 100 Pieces

Surface Finish : Coated Abrasive

Tool Type : Fiber Disc

Gauge : Standard

Grip Type : Requires Backing Pad Attachment

Send Inquiry

Send Inquiry